The railway company BLS sets a good example

Pioneer plant with salt battery for storing solar power

BLS is constantly modernising its technology and applying future-oriented innovative solutions. The new technical building and the switching station in Holligen/BE are powered by photovoltaics. The system was installed by the Ruswil-based company Alectron AG. A new feature was the storage of the electricity in a salt battery. This sustainable and ecological storage system was manufactured by Innovenergy GmbH from Meiringen. This system represents a pilot plant with an independent power supply.

The Holligen switching station supplies electricity to the railway lines in the direction of Neuenburg, Schwarzenburg, Fribourg and Bern railway station. With the chosen technology concept, in line with the federal government's energy strategy, BLS took its responsibility seriously and relied on sustainable building technology as well as environmentally friendly electricity storage using salt batteries. BLS is thus the first railway company to use this new technology in practice. The Menznau signal box also uses a salt battery to store electricity.

The heart, the salt battery

The beginnings of the technology come from South Africa in the 1980s. The salt batteries installed in the BLS system in Bern are produced by the company FZSoNick in Stabio/TI. These in turn were integrated by innovenergy from Meiringen into a battery storage system with UPS function and intelligent control. Battery Consult, also from Meiringen, has further developed and optimised the salt battery in recent years with the support of a Brazilian research project.

The FZsoNick salt battery has decisive advantages such as:

- It can neither burn nor explode

- It is 100% ecological and sustainable

- It is produced from abundant raw materials (including salt from the Swiss salt flats)

- It has a long lifespan of up to 25 years

- It takes up 3 times less space than lead batteries

- It is 100% recycled

- It works independently of the outside temperature

innovenergy's storage solution attracted a lot of attention at the Energy Storage Europa trade fair in Düsseldorf and the ees/Intersolar trade fair in Munich in 2019.

Sustainable concept for optimal energy consumption

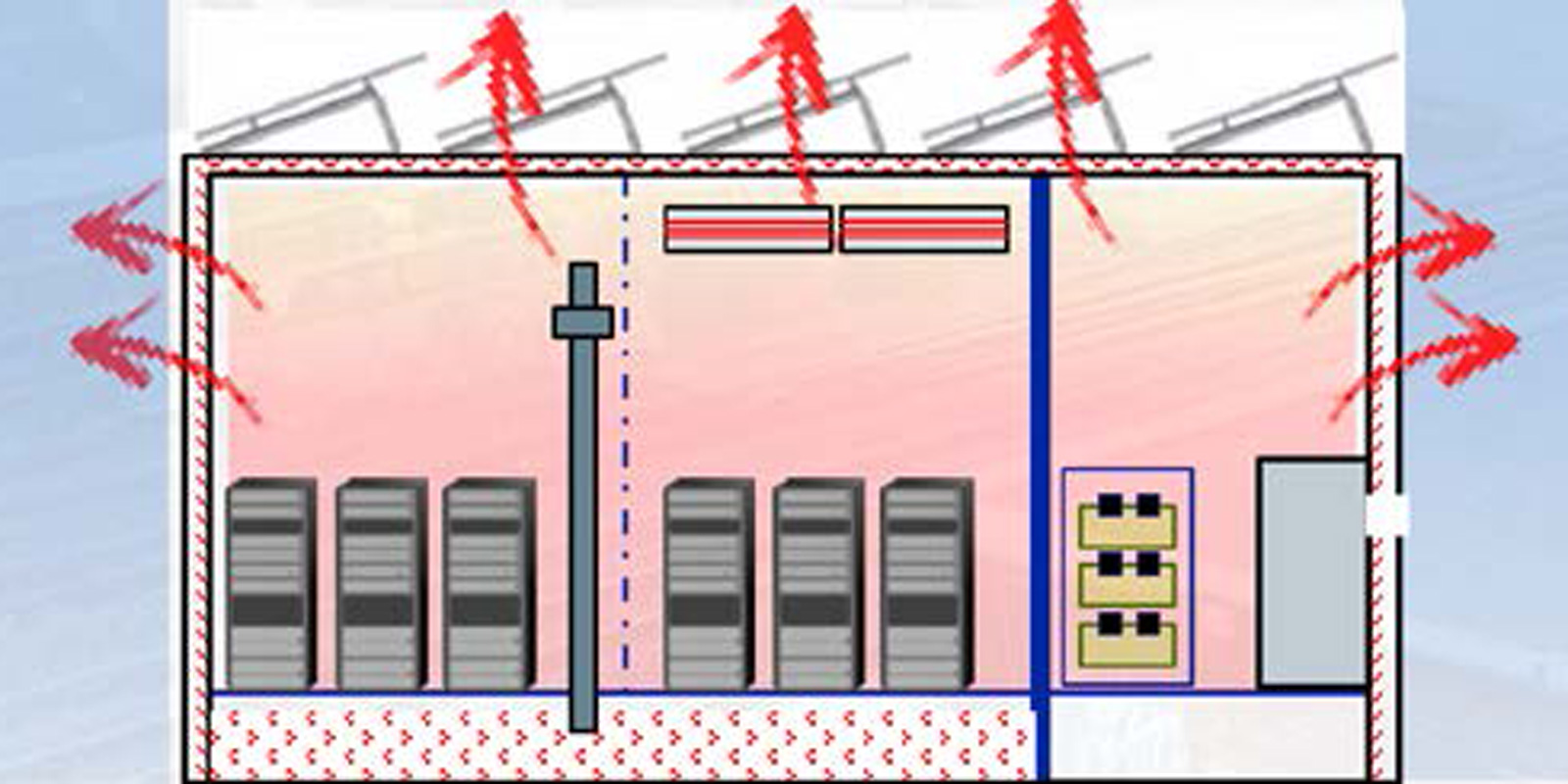

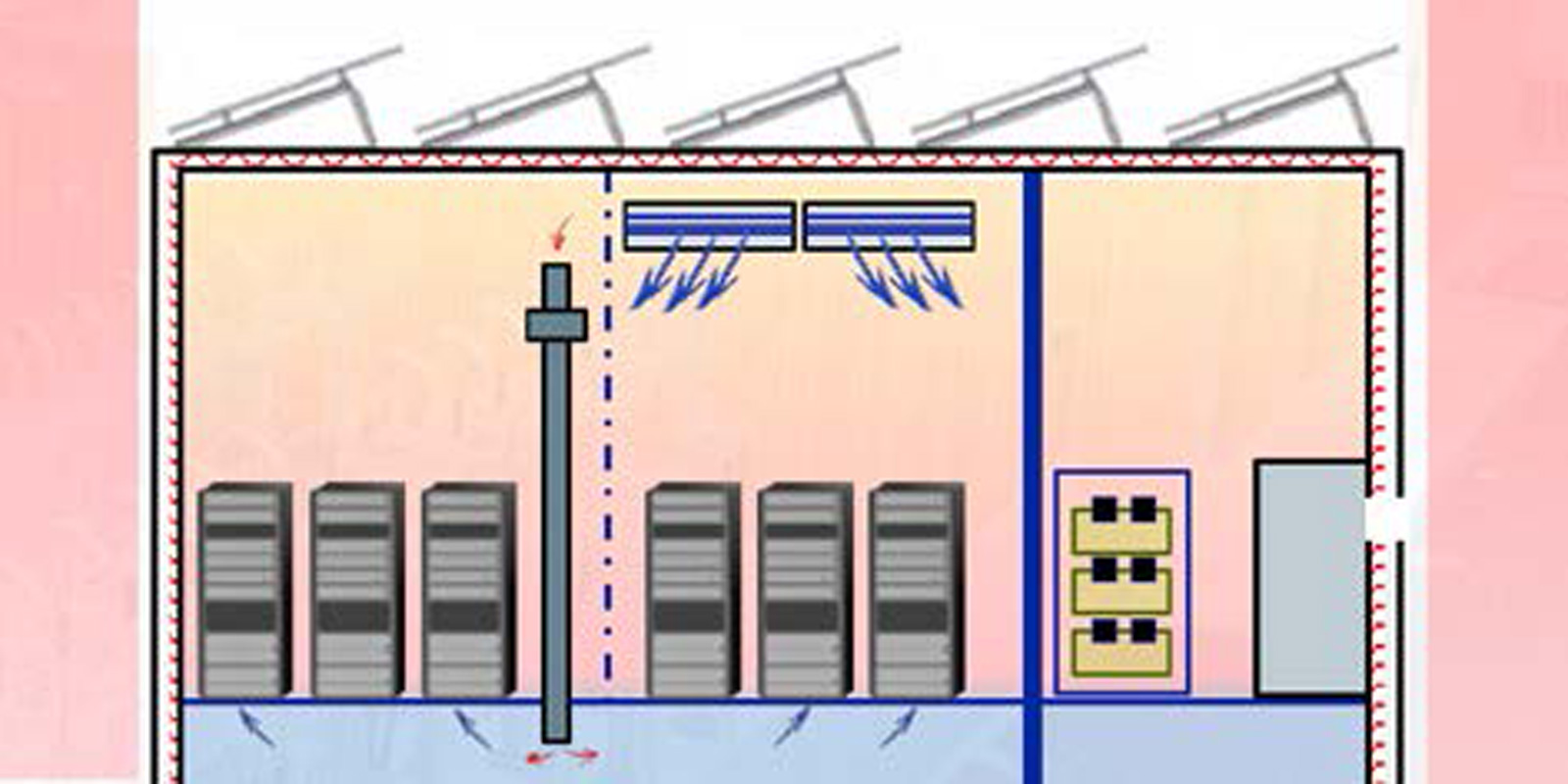

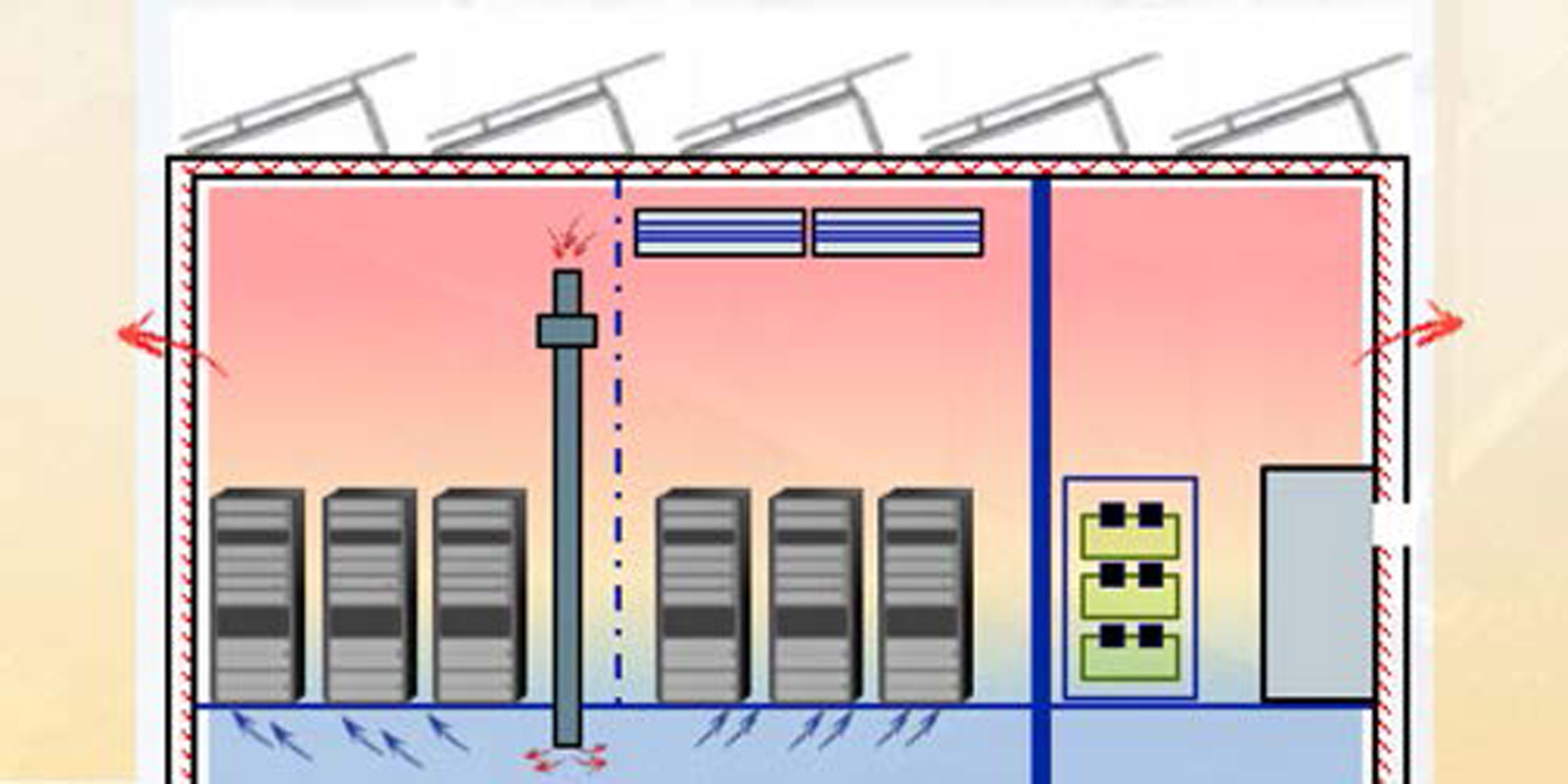

The special conditions for the indoor climate in the technical building had to be met. The technical equipment requires an indoor temperature of 10 to 26° C. The building was insulated to a lesser extent. This allows the excess heat given off by the technical equipment to escape through the building envelope. In winter, the outside air cools the rooms. There is a hollow floor that serves as thermal insulation. If this is not sufficient, the temperature can be regulated with the air-conditioning unit so that it does not drop below 10° C. In the transitional periods of spring and autumn, the indoor climate is regulated by circulating air. Warm air is fed into the hollow floor via a pipe. In summer, cool air is blown from the hollow floor into the room via the controlled ventilation. If this is not sufficient to cool the room, the air conditioning system is used.

The important power supply

A photovoltaic system is installed on the flat roof of the technical building. This supplies the necessary electricity for the technical equipment inside the building. The system used for the uninterruptible power supply (UPS), i.e. a real emergency power supply, is supplied by the salt battery. In the event of a power failure, the UPS system continues to supply power for half an hour. The advantage of the chosen solution is that only one storage battery system is required for the two functions "supply of the switching station" and "UPS system".

BLS is the first railway company to opt for a salt battery solution for power storage. Salt batteries consist of 32 % normal table salt, 22 % nickel, 22 % iron and 20 % ceramic. They are 100 % manufactured in Switzerland. Salt batteries have a longer life than conventional lead-acid or lithium-ion batteries. On average, they reliably perform their task for 20 years or more. The raw materials used are recycled again.

The cycle: PV system and salt battery storage system ensures a self-sufficiency level of 100 % for the railway technology system in summer. With the new strategy, BLS saves almost 2/3 of the energy required for cooling in its new technical building. This corresponds to the annual output of 14 refrigerators. The planned own energy production of the solar system covers an annual electricity demand of 3 to 4 households. In addition, further costs for operation and maintenance can be saved. In other words, this is an economically welcome solution in the long term.

The low-voltage system in the technical building and on the platform is supplied by the PV system and the independent salt battery. They guarantee safe operation at all times. BLS intends to continuously develop the concept of "independent energy storage" and thus make its infrastructure suitable for the future and efficient at further locations.

Asked …

by Elmar Bumann - Head of Structural Engineering BLS

What were the decisive reasons for choosing a salt battery storage system?As part of the Energy Strategy for Public Transport 2050 (ESÖV) from the Federal Office of Transport (BAV), BLS entered a larger project idea for solar power with sustainable battery storage using salt accumulators. When we were awarded the innovative project, we wanted to gain experience with the evaluated salt battery with a smaller project. The salt battery is sustainable and environmentally friendly, besides that it fulfilled all technical requirements.

Was it already possible to draw on practical experience?

Yes, with Battery Consult and Innovenergy, we had two partners in the project implementation who already had practical experience with the use of salt batteries. This existing expertise served as the basis for the further development of an energy management system that could be designed precisely to meet BLS's needs.

What is the price range for salt batteries compared to conventional batteries?

The salt battery is 10 - 15 % more expensive to purchase. However, in our LCC (life cycle costs) analysis, this battery saves costs and resources. Based on this result, the salt battery is cheaper than conventional batteries in the longer term. A positive and desired side effect is the clear benefit for the environment.

Did "teething troubles" have to be solved during commissioning or did everything work right from the start?

With careful planning of the photovoltaic system coupled with innovenergy's salt battery storage system, the implementation took place without any noteworthy problems. There were stumbling blocks when commissioning the uninterruptible power supply (UPS). Since BLS developed and implemented the first UPS system of this kind in Europe, these were factored into the risk assessment in advance. After a few optimisations, the system ran trouble-free.

Can you already say something about the operation so far? Has the step for this new technology been worth it?

The BLS building technicians have continuously recorded and monitored the data of the system. The photovoltaic system, the salt battery storage system and the UPS are running reliably and without any significant faults. The first evaluations tend to confirm the assumptions we projected. The experience gained is constantly being incorporated into the optimisation of the existing plant and serves as a basis for the implementation of all further comparable projects.

Further information:

BLS AG

Genfergasse 11

CH-3001 Berne

Telefon: +41 58 327 27 27

kundendienst@bls.ch

www.bls.ch